English

English

ZKSJ-1000

TKSAGE

| Availability: | |

|---|---|

| Quantity: | |

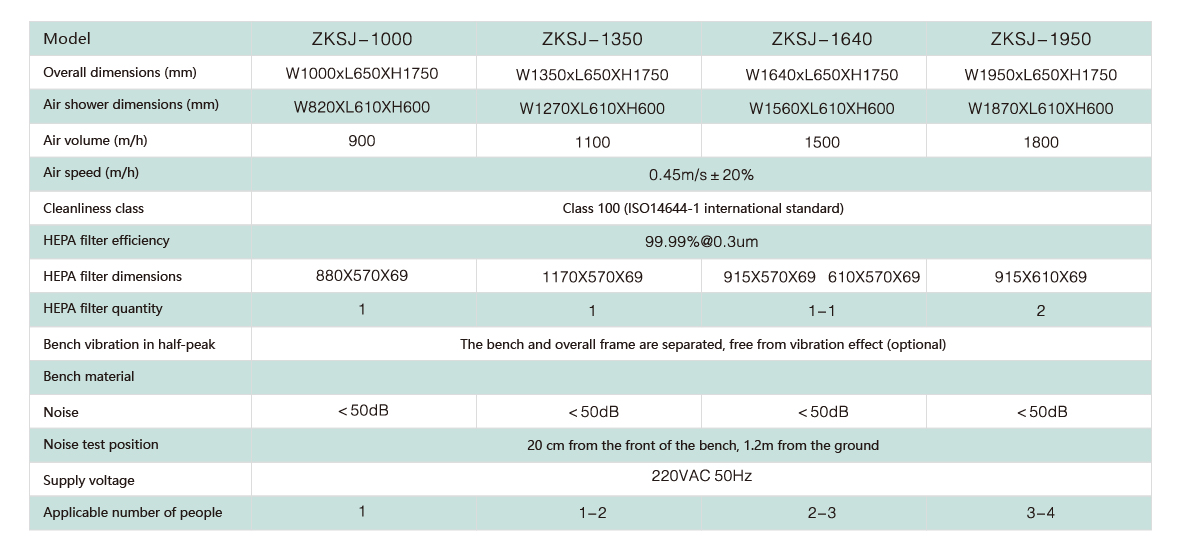

The vertical flow clean bench adopts the airflow form of vertical unidirectional airflow purification principle and combines low-noise centrifugal fan, plenum chamber and HEPA filter in a single unit structure. This product can adopt separated bench to reduce the impact of vibration.

It is a kind of air cleaning equipment with high versatility to provide local high clean environment, and its use has good effect on improving process conditions, improving product quality and increasing yield.

The TKSAGE Vertical Flow Clean Bench is a localized laminar airflow workstation designed to deliver Class 5 (ISO 14644-1) clean environments for precision operations. Its downward airflow pattern (0.45-1.2 m/s) creates a particle-free zone by sweeping contaminants away from the work surface into exhaust filters. Constructed with SUS304 stainless steel and featuring intelligent pressure monitoring, it’s ideal for labs, electronics assembly, and sterile processing where unidirectional clean air is critical.

PCR and gene sequencing require contamination-free sample handling. This clean bench provides HEPA-filtered vertical airflow over pipetting stations, preventing cross-contamination between DNA samples. The UV pre-sterilization function (30-minute cycle) eliminates residual nucleic acids, reducing false positives by 90%.

Manufacturing of OLED displays and fiber optic modules demands dust-free workspaces. The bench’s uniform airflow (±5% velocity variation) protects delicate components from particulate adhesion during soldering and bonding, improving yield by 15% compared to open-bench operations.

Microbiology labs use the bench for preparing culture media and inoculating Petri dishes. Its negative pressure plenum design prevents air leakage, while the 300 Lux LED lighting ensures clear visibility—complying with USP <797> guidelines for sterile compounding.

Class 5 Cleanliness: 99.99% HEPA filtration of 0.3μm particles; vertical airflow prevents cross-contamination better than horizontal models.

Smart Pressure Monitoring: LCD panel displays real-time differential pressure; alerts trigger when filter replacement is needed.

Ergonomic Design: Tiltable work surface (0-15°) reduces operator fatigue; front glass sash with smooth height adjustment (300-600mm).

Quiet Operation: ≤62 dB noise level, suitable for lab environments where acoustic comfort is required.

Custom Sizing: Work surface dimensions customizable from 800×600mm to 1800×800mm; wall-mounted/floor-standing options.

Installation & Training: On-site setup includes airflow velocity calibration and staff training on filter maintenance.

Warranty & Maintenance: 1-year machine warranty; free filter replacement guidance; annual PAO testing service available.

Compliance Documentation: Provide ISO 14644-1 certification, operation manuals, and calibration records.

A: Typically every 12-18 months, depending on usage; the pressure monitor alerts when differential pressure exceeds 250 Pa.

A: Yes, optional explosion-proof models (Ex d IIB T4) are available for hazardous material handling.

A: Adjustable from 0.45 m/s (minimal disturbance for cell cultures) to 1.2 m/s (high-particulate environments).