English

English

ZKSJ-1200-1

TKSAGE

| Availability: | |

|---|---|

| Quantity: | |

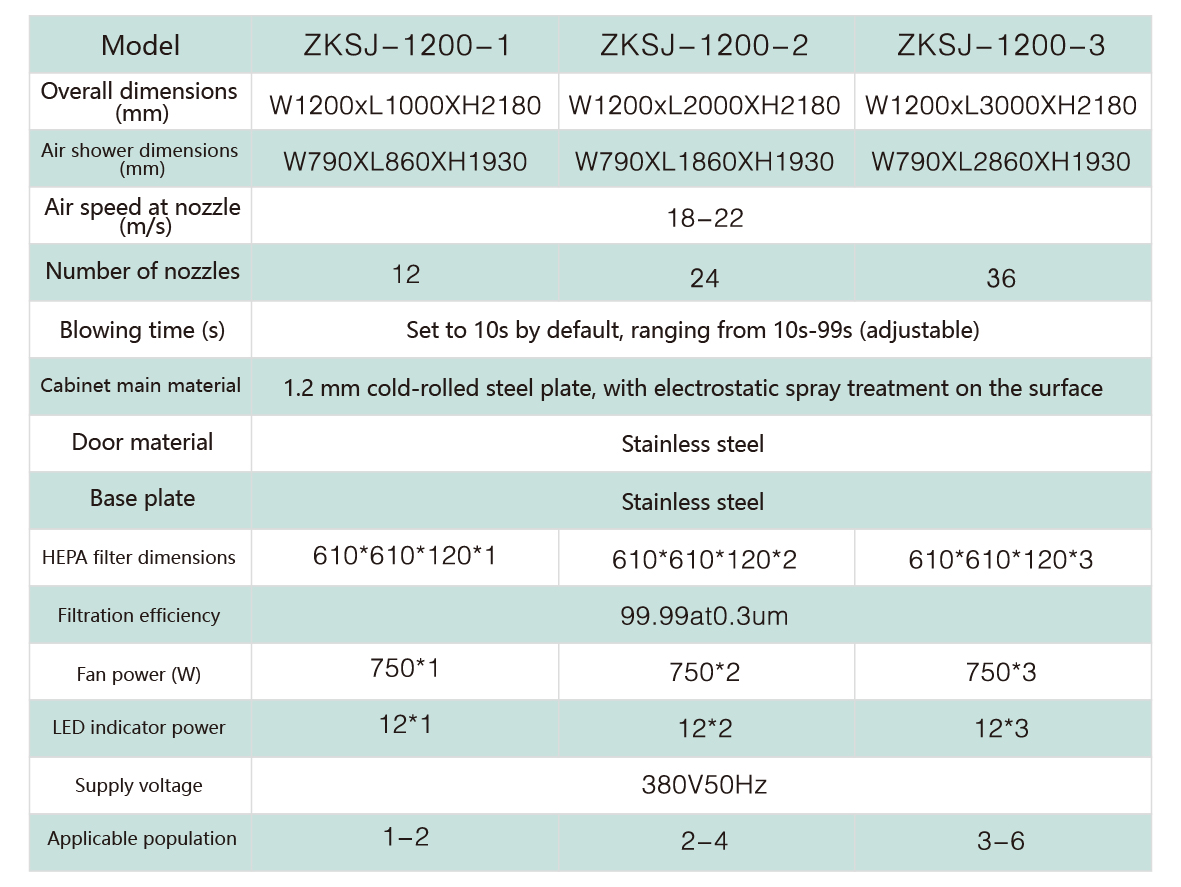

The product has three models (ZKSJ-1200-1/2/3) suitable for 1-2, 2-4, and 3-6 people respectively. It is widely used in the entrances of clean workshops in electronics, pharmaceuticals, food, and other industries. It integrates HEPA filtration, UV sterilization, and electrostatic elimination functions to ensure that personnel and goods meet the cleanliness requirements of clean zones.

For small pharmaceutical laboratories or precision electronic component assembly workshops, the ZKSJ-1200-1 model (suitable for 1-2 people) is installed at the entrance. Before entering the workshop, operators enter the air shower chamber. The 12 nozzles spray high-speed air flow (18-22 m/s) to remove dust from the surface of work clothes. The HEPA filter ensures that the sprayed air is clean, and the electrostatic eliminator removes static electricity, avoiding dust adsorption caused by static electricity.

In medium-sized food processing plants or vaccine production workshops, multiple operators need to enter the clean zone at the same time. The ZKSJ-1200-2 (2-4 people) or ZKSJ-1200-3 (3-6 people) model is selected. The extended air shower chamber (length 2000mm or 3000mm) and 24/36 nozzles ensure that each operator is fully blown. The adjustable blowing time (10s-99s) can be set according to the degree of contamination, improving the efficiency of personnel entry.

For small batches of goods (such as packaged electronic components or pharmaceutical raw materials) entering the clean room, the air shower can be used for dust removal. Place the goods on a trolley and push them into the air shower chamber. The high-speed air flow sprays the surface of the goods to remove attached dust. The UV sterilizer can be activated for secondary disinfection, ensuring that the goods meet the cleanliness standards of the clean room.

High-Speed Double-Side Blowing: Double-sided stainless steel nozzles with an air speed of 18-22 m/s. The nozzles are designed at a reasonable angle to cover the entire body and goods, achieving thorough dust removal.

Efficient Filtration System: Equipped with primary-efficiency filters and HEPA filters (filtration efficiency 99.99% at 0.3μm). The air is filtered twice before being sprayed, ensuring that the blowing air is free of contaminants.

Multi-Functional Protection: Integrates UV sterilizer, electrostatic eliminator, and automatic door device. It not only removes dust but also kills microorganisms and eliminates static electricity, providing comprehensive purification.

Intelligent Control: Adopts a touch LED/LCD digital display panel, with adjustable blowing time (default 10s). The IR sensor automatically starts the blowing process when detecting personnel or goods, and the indicator light clearly shows the working status.

Durable Structure: The cabinet is made of 1.2mm cold-rolled steel plate with electrostatic spray treatment. The inner wall and door are made of stainless steel, which is corrosion-resistant, easy to clean, and meets the hygiene requirements of industrial and laboratory environments.

Model Selection Consultation: According to the customer’s daily number of personnel, cargo volume, and entrance space size, recommend the most suitable model and provide layout design suggestions.

On-Site Installation and Commissioning: Professional technicians install the air shower, connect the power supply, debug the automatic door, sensor, and blowing system, and ensure that all functions are normal.

Operation and Maintenance Training: Train the customer’s staff on the use of the control panel, adjustment of blowing time, replacement of filters, and daily cleaning methods.

After-Sales Maintenance: Provide a one-year warranty. Regularly remind customers of filter replacement and UV lamp maintenance. For faults such as fan failure or sensor abnormality, provide remote troubleshooting or on-site repair services.

A1: The supply voltage is 380V 50Hz. It is necessary to ensure stable power supply during use. A dedicated circuit is recommended to avoid voltage fluctuations affecting equipment performance.

A2: The primary-efficiency filter should be replaced every 3-6 months, and the HEPA filter should be replaced every 12-18 months. The replacement cycle can be adjusted according to the usage frequency and the dust concentration in the environment. The control panel will display a reminder when the filter is blocked.

A3: The standard model is not suitable for explosion-proof environments. If you need to use it in explosive or flammable environments, please inform our sales team in advance. We can provide customized explosion-proof air shower solutions that meet relevant safety standards.

| 1. Fan | 1. Stainless steel cabinet |

| 2. Primary-efficiency filter | 2. Stainless steel inner wall |

| 3. Stainless steel nozzle | 3. UV sterilizer |

| 4. HEPA filter | 4. Electrostatic eliminator |

| 5. Tempered glass window | 5. Automatic door device |

| 6. Indicator light |  |

| 7. Door closer | |

| 8. IR sensor | |

| 9. Control panel |