English

English

ZKSJ-1290-1

TKSAGE

| Availability: | |

|---|---|

| Quantity: | |

| 1. Double-speed fan | 2. Primary-efficiency filter (with mesh) | 3. Stainless steel nozzle | 4. Separator-free HEPA filter |

| 5. Tempered glass window | 6. Indicator light | 7. Entrance door closer | 8. IR sensor | |

| 9. Control panel (with plexiglass cover) | 10. Magnetic lock | 11. E-stop switch (total 3) | 12. Anchor bolt (M12) 13. Pressure relief opening |

Optional accessories:

| 1. Stainless steel cabinet | 2. Stainless steel inner wall | 3. UV sterilizer |

| 4. Electrostatic eliminator | 5. Automatic door device | 6. Differential pressure gauge |

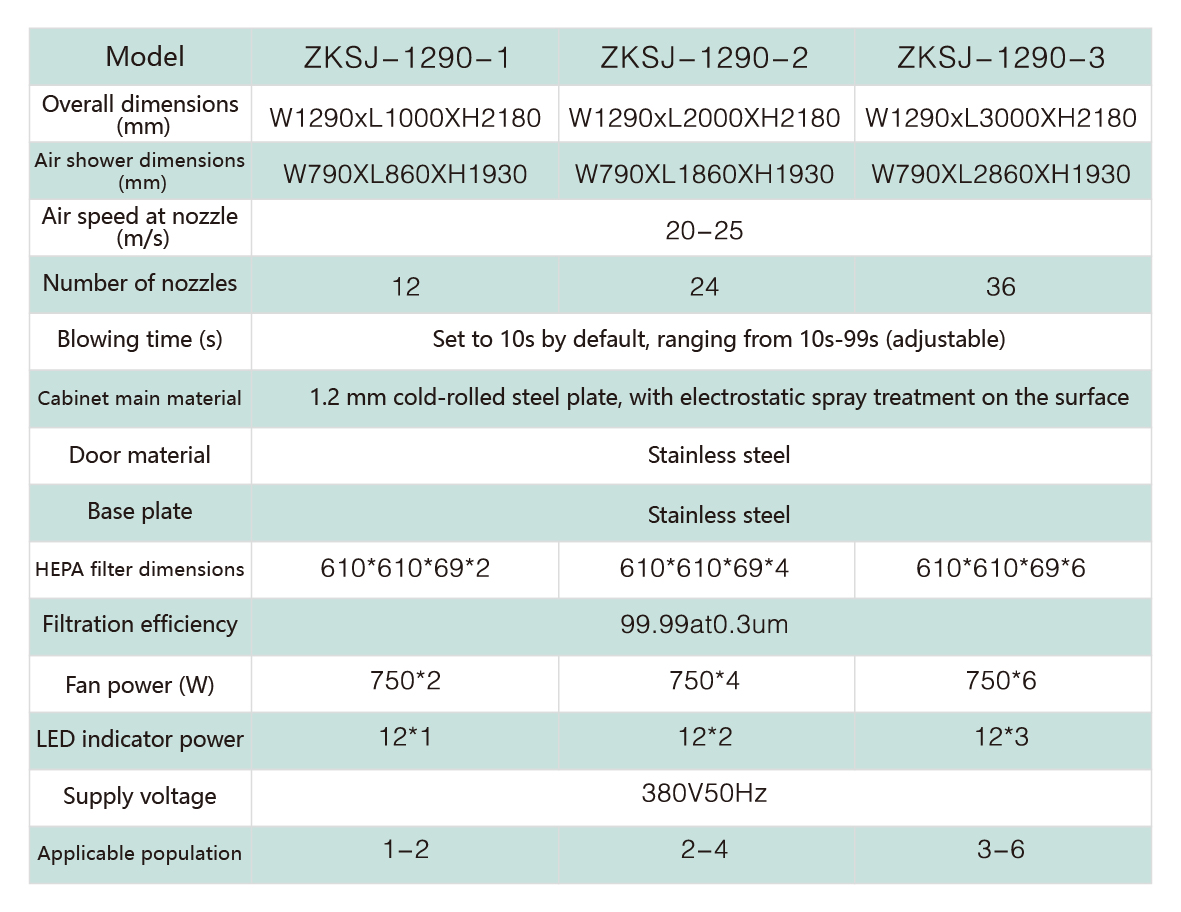

The 1290 Double-Side Blowing Air Shower is a high-performance air purification device designed for personnel decontamination before entering cleanrooms. As a core product of TKSAGE, it integrates double-speed fan technology, high-efficiency filtration, and intelligent sensing to remove dust particles from human bodies and clothing effectively. With adjustable blowing time and multi-model options, it meets the cleanliness requirements of various industries, ensuring that unpurified air and contaminants are blocked outside cleanrooms, thus maintaining the internal hygiene level of controlled environments.

In pharmaceutical workshops and biotech labs, strict contamination control is critical for product quality and safety. The 1290 Double-Side Blowing Air Shower serves as a mandatory passage for staff entering production areas. Its high-speed blowing (20-25 m/s) and 99.99% HEPA filtration efficiency (at 0.3μm) eliminate dust, hair, and other particles that may carry microorganisms, complying with GMP standards and reducing the risk of product contamination.

Electronic components are highly sensitive to dust, which can cause short circuits or performance failures. This air shower is installed at the entrance of cleanrooms for chip production, circuit board assembly, and LCD manufacturing. The stainless steel nozzles deliver uniform airflow from both sides, ensuring thorough cleaning of operators’ overalls, shoes, and tools, protecting precision equipment and improving product yield.

Food safety requires strict control of external contaminants. The air shower is suitable for food packaging and processing workshops. It removes dust, lint, and potential impurities from workers’ clothing, preventing cross-contamination during food production. Optional UV sterilizer accessories further enhance hygiene by inhibiting microbial growth, meeting food industry hygiene regulations.

Dual-Speed Fan Technology: Automatically switches to high-speed blowing when personnel enter and low-speed self-cleaning (10-99s adjustable) when exiting, maintaining long-term cleanliness and better decontamination than traditional models.

High-Efficiency Filtration System: Equipped with primary-efficiency filters (with mesh) and separator-free HEPA filters, achieving 99.99% filtration of 0.3μm particles for pure airflow.

Intelligent & Safe Design: IR sensors trigger automatic operation, while magnetic locks and 3 emergency stop switches ensure operational safety. Tempered glass windows allow real-time observation.

Multi-Model Customization: Three models with different sizes and nozzle quantities (12/24/36) support 1-6 users, adapting to various space and throughput needs.

As an integrated manufacturer, we offer end-to-end services for the 1290 Double-Side Blowing Air Shower:

Customization Service: Tailor overall dimensions, inner wall materials (optional stainless steel), and accessories (electrostatic eliminator, automatic door) according to customer URS files.

Professional Installation: Our team provides on-site installation, commissioning, and training to ensure correct operation.

After-Sales Maintenance: Offer 1-year warranty for core components (fan, filter), regular maintenance reminders, and fast replacement of wearing parts.

Technical Consultation: 24/7 online support for product operation, troubleshooting, and cleanliness optimization.

A: The nozzle air speed reaches 20-25 m/s, which is sufficient to remove stubborn dust particles from clothing and skin.

A: Yes, the default blowing time is 10s, and it can be adjusted between 10s-99s to meet different decontamination requirements.

A: The product uses 380V 50Hz power supply, and the fan power ranges from 1500W to 4500W based on the model.