English

English

ZKSJ-1920-1

TKSAGE

| Availability: | |

|---|---|

| Quantity: | |

| 1. Double-speed fan | 2. Primary-efficiency filter |

| 3. Stainless steel nozzle (360-degree rotation) | 4. Separator-free HEPA filter |

| 5. Tempered glass window | 6. Indicator |

| 7. Entrance door closer | 8. IR sensor |

| 9. Control panel (with plexiglass cover) | 10. Magnetic lock |

| 11. E-stop switch (total 3) | 12. Anchor bolt (M12) |

| 13. Pressure relief opening | |

| 1. Stainless steel cabinet | 2. Stainless steel inner wall | 3. UV sterilizer |

| 4. Electrostatic eliminator | 5. Automatic door device | 6. Differential pressure gauge | |

| Three-side blowing air shower features: The traditional side-blowing air shower blows turbulence, which is easy to form a vortex when blowing toward personnel and will not take away the dust immediately, thus causing reattainment of dust. However, the three-side blowing air shower blows air from the top down to quickly take away the dust through the bottom mesh under the combined action of gravity, so as to achieve the best blowing effect. | |||

The 1290 Three-Side Blowing Air Shower is a next-generation personnel and material decontamination system engineered by TKSAGE for stringent cleanroom access control. Unlike traditional two-side models, it integrates three-dimensional airflow technology, high-velocity nozzles, and intelligent sensing to eliminate 99.99% of 0.3μm particles from garments, tools, and small cargo. As a core cleanroom barrier solution, it maintains positive pressure differentials and blocks unfiltered air intrusion, complying with ISO 14644-1 and GMP standards across industries.

In Class 100 to Class 1000 semiconductor facilities, even microscopic dust can cause wafer defects. This air shower installed at fab entrances delivers 25 m/s airflow from left, right, and top sides, removing static-charged particles from operators’ anti-static suits and wafer carriers. Its electrostatic eliminator accessory prevents ESD damage to sensitive 7nm/5nm chips.

Biologic drug production requires sterile personnel access. The air shower serves as a mandatory decontamination checkpoint before aseptic filling rooms, eliminating microbial carriers (hair, skin flakes) via triple-sided airflow. Optional UV-C sterilization post-blowing further reduces bioburden, aligning with FDA 21 CFR Part 11 requirements.

Manufacturers of implantable devices (pacemakers, stents) rely on this air shower to decontaminate assembly tools and staff. Its adjustable blowing time (10-99s) accommodates different contamination levels, ensuring no particulates enter critical assembly zones—reducing post-sterilization rework rates by 40%.

Tri-Directional Airflow System: 36 stainless steel nozzles (12 per side) create 3D airflow coverage, eliminating blind spots compared to dual-side models.

Dual-Speed EC Fans: Auto-switch to 25 m/s for decontamination and 8 m/s for self-cleaning, cutting energy consumption by 30% vs. conventional fans.

Smart Interlock Control: IR sensors trigger automatic operation; magnetic locks prevent simultaneous door opening, maintaining cleanroom pressure integrity.

Durable Construction: SUS304 stainless steel interior with rounded corners for easy disinfection; corrosion-resistant exterior withstands harsh cleaning chemicals.

Customization: Tailor nozzle quantity (24/36/48), cabinet size, and accessories (electrostatic eliminator, UV lamp) per URS documents.

Turnkey Installation: Certified technicians handle on-site setup, airflow calibration, and PAO leak testing to validate performance.

Maintenance Program: 1-year warranty on fans/filters; quarterly maintenance reminders; 48-hour delivery of replacement HEPA filters.

Compliance Support: Provide calibration certificates, GMP validation documents, and ISO 14644-1 test reports.

A: Supports 2-3 users simultaneously with a chamber size of W1500×L2000×H2100 mm; custom models for 4+ users available.

A: Yes, optional RS485 port connects to BMS for real-time airflow monitoring and remote operation logs.

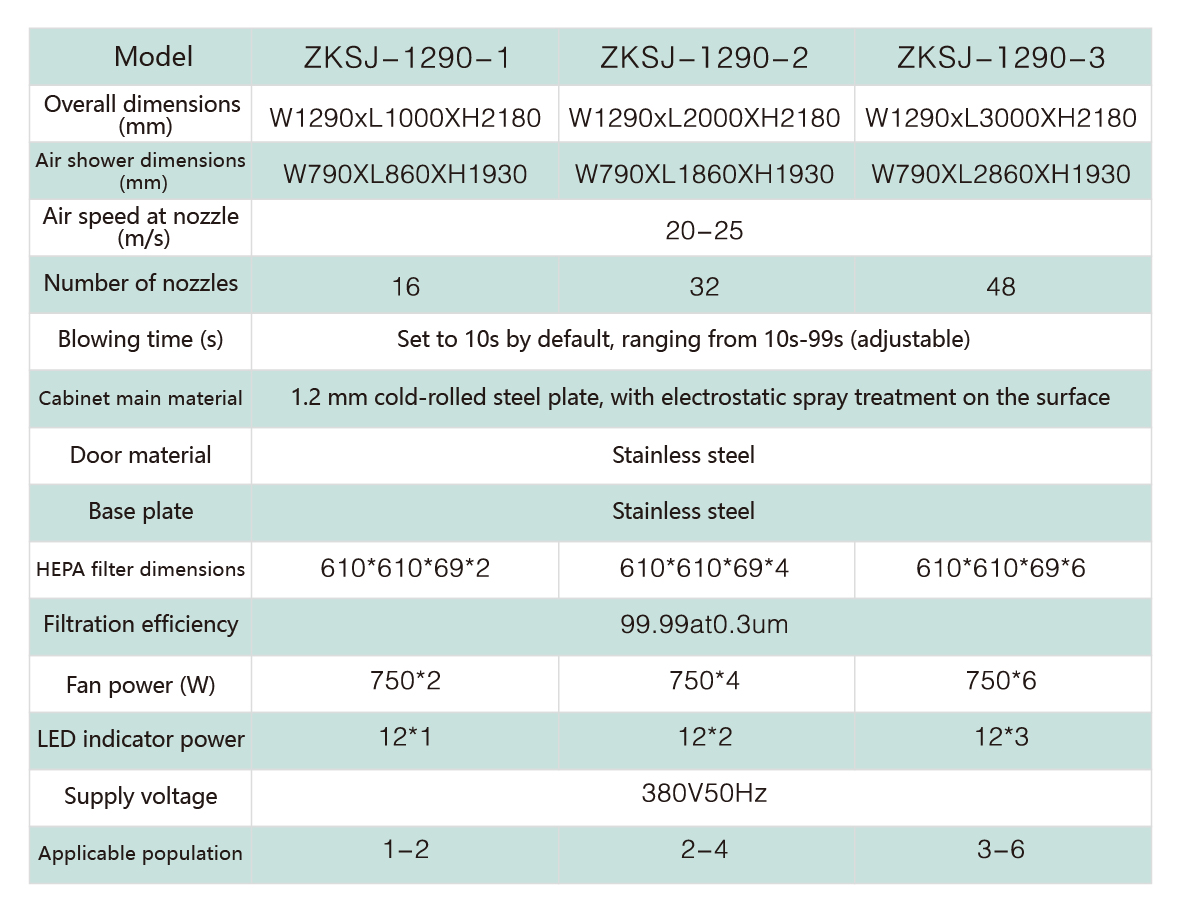

A: 380V 50Hz, with fan power ranging from 2200W (24-nozzle) to 4500W (48-nozzle) models.