English

English

ZKSJ-2000-2

TKSAGE

| Availability: | |

|---|---|

| Quantity: | |

| 1. Double-speed fan | 2. Primary-efficiency filter | 3. Stainless steel nozzle | 4. Separator-free HEPA filter |

| 5. Tempered glass window | 6. Indicator light | 7. E-stop switch (total 3) | 8. IR sensor |

| 9. Control panel (with glass cover) | 10. Anchor bolt (M12) | 11. Entrance door closer | |

| Optional accessories: | ||||

| 1. Stainless steel cabinet | 2. Stainless steel inner wall | 3. UV sterilizer | 4. Electrostatic eliminator | 5. Automatic door device |

The 2000 Cargo Air Shower Series is a specialized decontamination equipment designed for cargo entering cleanrooms. Developed by TKSAGE, it addresses the contamination risks caused by goods transportation, featuring electronic interlocking doors, intelligent voice prompts, and 360° air blowing. The series uses high-efficiency filtration and double-speed fan technology to remove dust, debris, and other contaminants from cargo surfaces, acting as an air lock to prevent unpurified air from entering cleanrooms. It is an essential device for logistics, food, electronics, and pharmaceutical industries.

In food processing and packaging plants, raw materials, packaging materials, and finished products need strict decontamination. The 2000 Cargo Air Shower cleans cartons, pallets, and containers, removing dust, insects, and impurities. The optional UV sterilizer kills microorganisms on cargo surfaces, ensuring food safety during storage and transportation.

Electronic components (such as circuit boards, chips) are often transported in batches, and surface dust can affect product quality. This cargo air shower is installed at the entrance of electronic cleanrooms, cleaning large quantities of goods with high-speed airflow (20-25 m/s) and HEPA filtration, protecting production lines from contamination.

Pharmaceutical raw materials and packaging materials must meet GMP standards. The air shower’s double-door interlocking design prevents air exchange between clean and non-clean areas. Its adjustable blowing time (10-99s) ensures thorough decontamination of sacks, barrels, and other packaging, reducing the risk of cross-contamination in pharmaceutical production.

Comprehensive Decontamination: Rotatable stainless steel nozzles deliver airflow from all directions, covering every corner of the cargo for effective dust removal.

Intelligent Operation: Equipped with an intelligent voice prompting system that guides users during blowing, and IR sensors for automatic operation.

Double-Door Interlocking: Electronically interlocked doors prevent simultaneous opening, acting as an air lock to maintain cleanroom pressure.

Durable Structure: 1.2 mm cold-rolled steel cabinet with electrostatic spray treatment, and stainless steel base plate for corrosion resistance and easy cleaning.

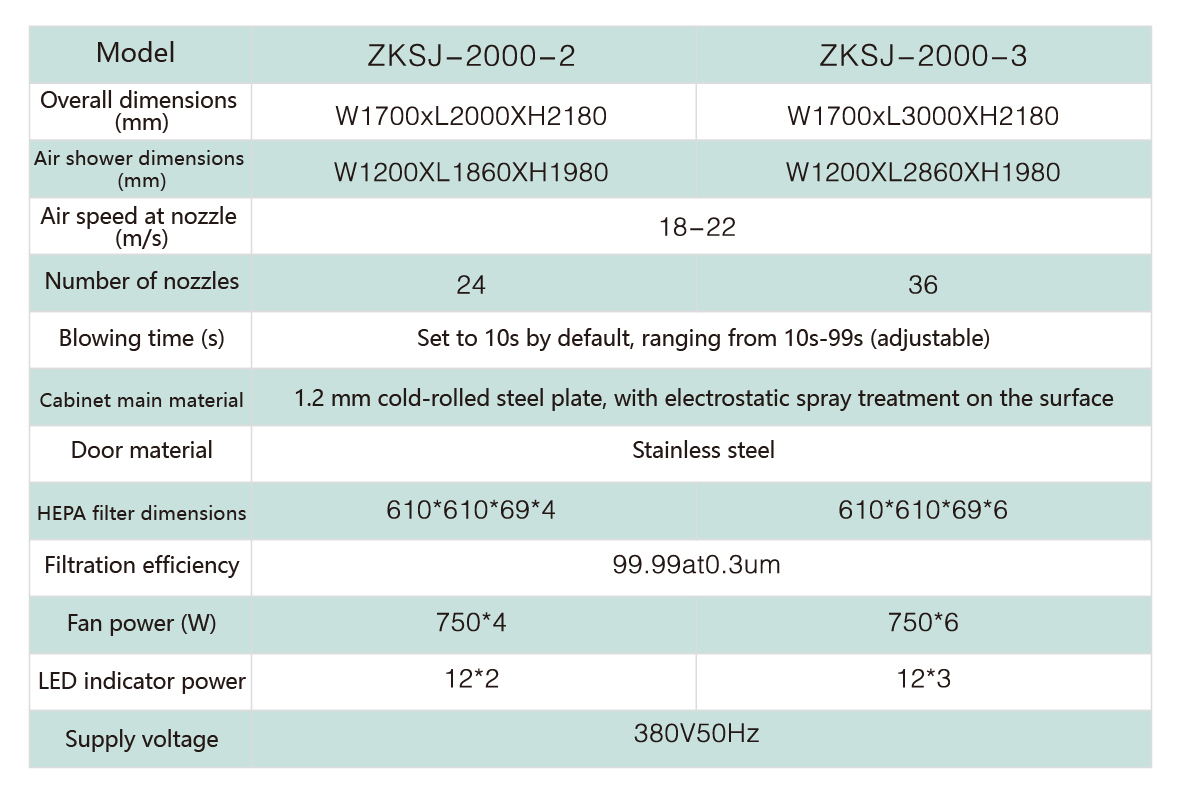

Multi-Model Options: Two models with different lengths, supporting 24-36 nozzles and adapting to cargo of various sizes.

As a professional manufacturer, we offer full-cycle services for the 2000 Cargo Air Shower Series:

Customization: Tailor cabinet materials (optional stainless steel), accessories (electrostatic eliminator, automatic door), and dimensions according to cargo size and cleanroom requirements.

Installation & Debugging: On-site installation by experienced technicians, including door interlocking calibration and airflow testing.

After-Sales Maintenance: 1-year warranty for core components, regular maintenance reminders, and fast delivery of replacement parts (filters, nozzles).

Technical Consultation: 24/7 online support for equipment operation, troubleshooting, and decontamination efficiency optimization.

A: One model has air shower dimensions of W1200×L1860×H1980 mm, and the other is W1200×L2860×H1980 mm, suitable for most standard cargo.

A: Yes, it is equipped with 3 emergency stop switches to ensure safe operation in case of abnormalities.

A: One model has a fan power of 750W×4=3000W, and the other is 750W×6=4500W.