English

English

TKSAGE has independently developed a forced shower system utilized in specialized environments to ensure the adaptability of personnel working in high biological risk areas when exiting negative pressure areas (toxic areas). This design is specifically applicable to P3/P4 biosafety laboratories or pharmaceutical plants with high disinfection and sterilization requirements. It features robust isolation capabilities and a focus on performance, ensuring the se para - tion and sealing between the negative pressure or core area (toxic area) and ordinary areas.

| Availability: | |

|---|---|

| Quantity: | |

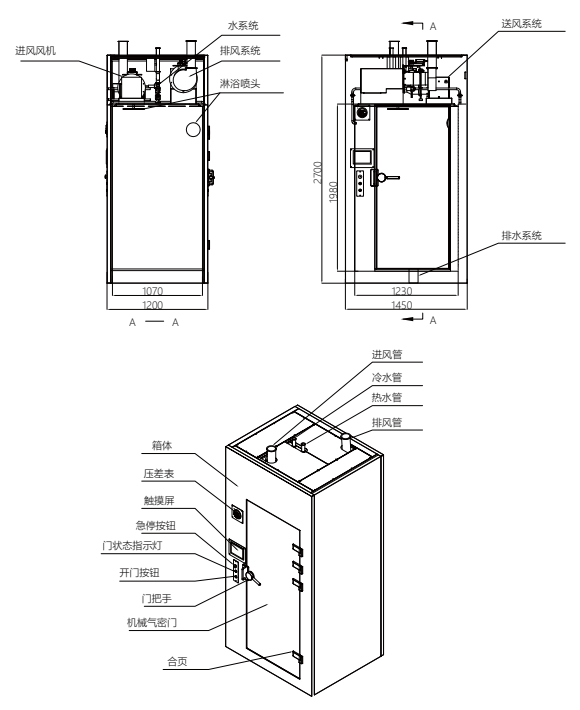

The Fog Shower Room is an independently developed forced shower system by TKSAGE, designed for personnel exiting negative pressure (toxic) areas in high biological risk environments. Specifically applicable to P3/P4 biosafety laboratories and pharmaceutical plants with strict disinfection requirements, it ensures isolation and sealing between negative pressure/core areas and ordinary areas. Constructed with 304 sanded board and round tube, it integrates air intake, exhaust, water supply, drainage, and pressure differential systems, plus a touchscreen + PLC + sensor control system. With external dimensions of 1450*1200*2700mm and internal dimensions of 1230*1070*1980mm, it provides a safe and efficient disinfection shower experience for personnel.

Personnel working in P3/P4 laboratories handling highly pathogenic microorganisms must undergo thorough disinfection before exiting the negative pressure area. The fog shower room’s forced shower system (hot/cold water adjustable) and negative pressure maintenance prevent pathogen leakage. The interlock system ensures airtight doors cannot be opened simultaneously, blocking cross-contamination between the laboratory and ordinary areas.

For pharmaceutical plants producing toxic or high-potency drugs (e.g., chemotherapy drugs, hormone preparations), personnel exiting the negative pressure production area need effective decontamination. The shower room’s air intake/exhaust system maintains negative pressure, while the forced shower removes residual toxins from clothing and skin. The backflow prevention device in the drainage system prevents toxic gas or water backflow.

In research facilities handling emerging pathogens or bio-toxins, the fog shower room provides a critical decontamination step for personnel. The touchscreen control system allows setting of shower time, water temperature, and pressure parameters, while the emergency stop button ensures safety in emergencies. The 304 stainless steel construction resists corrosion from disinfectants used in high-risk environments.

Forced shower system with adjustable hot/cold water (automatically regulated via settings) ensures thorough personnel decontamination.

Integrated air intake, exhaust, and pressure differential systems maintain internal negative pressure, preventing pollutant leakage.

Dual airtight doors with interlock system: doors cannot be opened simultaneously, avoiding cross-contamination.

304 stainless steel construction (T=2.0mm) for corrosion resistance and easy cleaning with disinfectants.

Touchscreen + PLC + sensor closed-loop control system enables real-time monitoring and adjustment of equipment status.

Drainage system with water trap and backflow prevention device, blocking gas and water backflow.

Equipped with safety features: emergency stop button, door status indicator, and pressure differential gauge for real-time monitoring.

We provide comprehensive technical support for high-risk environment applications. Services include customized shower room design based on facility layout and decontamination requirements, on-site installation and system integration (connecting to hot/cold water, air supply, and electrical systems), and operator training (covering control system operation and emergency procedures). We offer regular maintenance services (e.g., sealing ring replacement, system calibration) and supply genuine parts (e.g., shower heads, sensors). Additionally, we provide validation documentation, including pressure differential test reports and corrosion resistance certificates, to meet biosafety and pharmaceutical regulatory requirements.

A1: The shower room requires AC220V/50HZ power (2.0kw) and connection to factory-provided hot and cold water sources. The water temperature can be automatically adjusted between 30-45℃ via the touchscreen, and the system includes a flow control valve to ensure stable water pressure.

A2: The standard recommended shower time is 3-5 minutes, sufficient for removing residual contaminants. The touchscreen allows setting custom shower durations (1-10 minutes) based on facility decontamination protocols. The system will alert personnel when the shower cycle is complete.

A3: The standard model accommodates one person at a time. For high personnel flow (e.g., large-scale pharmaceutical plants), we offer customized multi-station shower rooms with expanded internal dimensions and additional shower heads, while maintaining the same isolation and sealing performance.