English

English

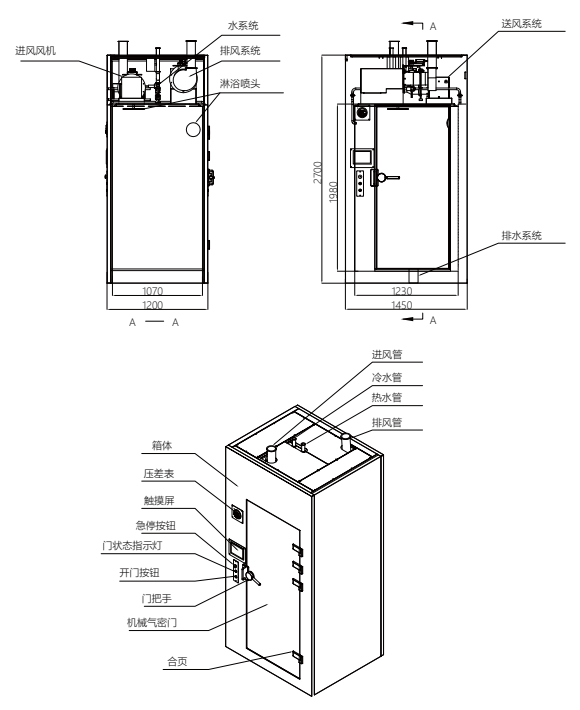

TKSAGE has independently developed a forced shower system utilized in specialized environments to ensure the adaptability of personnel working in high biological risk areas when exiting negative pressure areas (toxic areas). This design is specifically applicable to P3/P4 biosafety laboratories or pharmaceutical plants with high disinfection and sterilization requirements. It features robust isolation capabilities and a focus on performance, ensuring the se para - tion and sealing between the negative pressure or core area (toxic area) and ordinary areas.

| Availability: | |

|---|---|

| Quantity: | |

The Intensive Shower Room is a heavy-duty decontamination system designed for personnel and cargo entering high-level clean zones. Featuring 360° rotating nozzles (24-36 units) and 35m/s high-pressure airflow, it removes 99.9% of particles ≥0.5μm from protective clothing, tools, or equipment surfaces. Available in single-person (1200×1000×2100mm) and multi-person (2000×1500×2100mm) models, it integrates HEPA filtration, UV sterilization, and electrostatic elimination—ideal for pharmaceutical, food processing, and semiconductor industries.

Poultry processing plants use multi-person intensive shower rooms at the entrance of cooked food production zones. The 30-second high-pressure water-air hybrid spray removes feathers and contaminants from workwear, while the built-in water heater maintains 40℃ spray temperature to comply with FDA sanitation standards.

Vaccine production facilities require operators to pass through the shower room before entering Class 100 cleanrooms. The system’s sequential spray (head → torso → legs) ensures no blind spots, and UV sterilization (post-shower) eliminates residual microorganisms on clothing surfaces.

Wafer transport carts entering lithography workshops undergo cargo-specific intensive showers. Adjustable nozzle angles target cart wheels and crevices, with HEPA-filtered air preventing secondary contamination of 14nm chips.

High-Pressure 3D Spray: 35m/s airflow + optional 0.3MPa water spray (hybrid mode) covers all surfaces, with nozzle angle adjustable ±30°.

Dual-Filtration System: Primary filter (G4) + HEPA H14 filter ensures 99.995% particle removal from spray air, avoiding cross-contamination.

Intelligent Control Panel: 7-inch touchscreen with customizable spray programs (10-99s), IR sensor for automatic activation, and fault self-diagnosis.

Hygienic Construction: 304 stainless steel inner chamber (seamless welding, Ra≤0.8μm) with sloped floor for rapid drainage and easy CIP cleaning.

Customization: Tailor nozzle quantity, chamber size, and functions (water spray/UV) based on contamination level and space constraints.

Installation & Commissioning: On-site assembly, airflow velocity testing, and calibration of spray timing sequences to meet GMP requirements.

Training Programs: Operator training on program setting, filter replacement, and daily maintenance (e.g., nozzle clog cleaning).

After-Sales: 1-year warranty, free filter replacement for the first 6 months, and 48-hour on-site repair response in major industrial zones.

A1: Intensive models feature 35m/s airflow (vs. 22m/s standard) and optional water spray, removing sticky contaminants (e.g., oil, food residues) that standard air showers cannot handle.

A2: Yes, cargo-specific models have reinforced floors (1000kg load capacity) and wider door openings (1200mm). We recommend separate units for personnel and cargo to maintain efficiency.

A3: The system has double-layer waterproofing and water level sensors. If leakage occurs, it automatically stops water supply and triggers an alarm. Our technicians provide on-site sealing repairs within 24 hours.